Agriculture

Regulatory changes, coupled with expanding markets for organic foods, are driving the need for reducing or eliminating the addition of chemical fumigants to the soil. Fumigants are used to control weeds, pathogens and other soil-borne diseases, thereby improving crop yield and quality. However, these materials can have negative environmental impacts. To address these markets, PCI is developing a compact, lightweight catalytic steam generator as an alternative to conventional soil infestation control. Building upon our extensive experience in catalytic reaction applications, and working with the USDA under a Phase II SBIR program, PCI’s technology provides a mobile, high-volume steam solution that will enable large scale utilization of steam to improve yields on a wide range of crops.

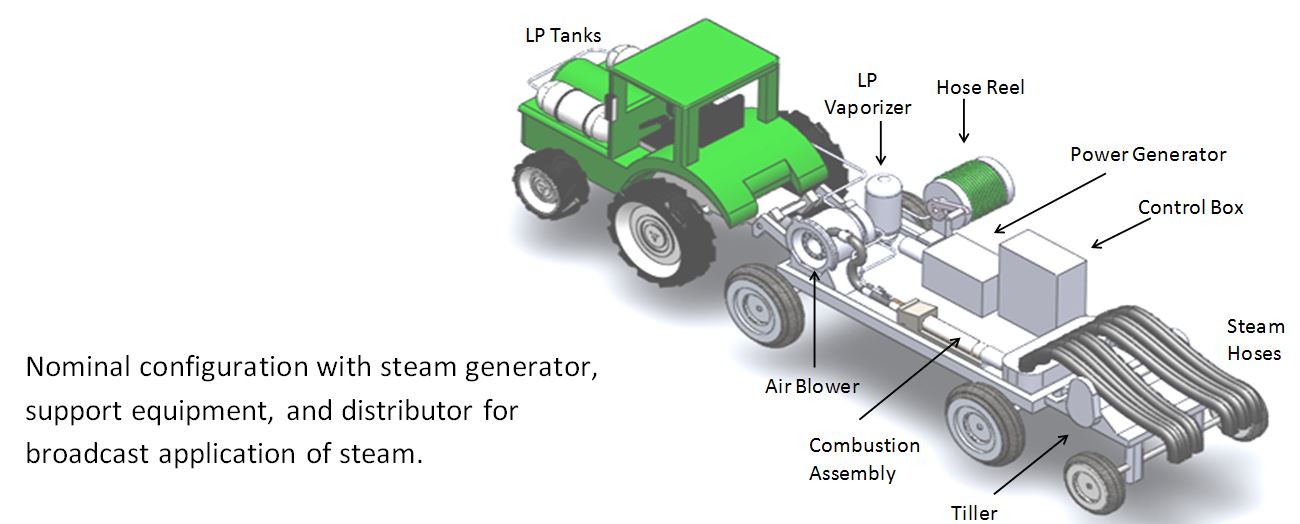

Steam has long been known as a highly effective method to control pathogens, insects, nematodes and weeds but, up until now, steam has not been economically viable for large acreage operations. PCI's compact steam generator is a practical alternative to fumigant soil disinfestation, offering chemical-free pathogen/weed control as effective as that now provided by methyl bromide (MB) or other fumigant packages, including chloropicrin. Utilizing readily available propane or natural gas as a fuel source for our proprietary catalytic burner, we create large quantities of steam where we can control the temperature, pressure and moisture content – all of which are important factors in treatment depth and effectiveness. Our steam generator is integrated with other balance-of-plant hardware on a tractor-pulled or self-propelled machine for high-rate, high-efficiency steam treatment of planting beds and soils.

Applications include any higher value crop: strawberries, cut flowers, landscaping trees and shrubs, herbs, etc. With the use of alternate steam delivery tools (e.g. augers), this technology can be packaged to treat tree farms, orchards and similar areas where the situation requires a targeted solution.

PCI’s product offers the advantage of being chemical free while providing similar performance and cost as leading chemical fumigants. Our device also brings into production those arable “buffer zones” where chemicals are prohibited, e.g. housing, schools, and other sensitive areas. For organic growers, the prospect of controlling pests, weeds, and other undesirables is very attractive given the inability to use conventional chemicals. Steam treatment is an opportunity to grow higher quality products, improve crop yields, reduce production cost, and increase market penetration.

For more, please check out our press releases:

- Precision Combustion Inc. (PCI) has been awarded a DOE SBIR Phase I Grant for Steam –Based In-Situ Soil Remediation

- PCI Awarded New USDA Grant for Agricultural Steam Generator for Soil Disinfestation

Contact PCI to learn more about how our solutions may be adapted for your needs.

OUR CUSTOMERS INCLUDE BOTH FEDERAL GOVERNMENT AND INDUSTRIAL BUSINESSES

PCI is developing advanced catalytic reactors and systems for a variety of markets. We invite you to explore some of our applications we are developing in the following markets: