TACTICAL POWER GENERATION

PCI has developed a family of soldier power gensets targeted to fill the capability gap for lightweight, portable power generation. These generators use COTS gasoline engines that are modified to use tactical fuels (JP-8, Jet A JP-5, DF2, etc.) using PCI’s fuel conditioning technology. These devices have been tested to meet the harsh environmental and operations demands of the US Military and are easy to start, operate and maintain. These generators have been selected for development by the US Army for their Platoon Power Generation (PPG) and Small Tactical Electric Power (STEP) Lightweight programs.

PCI has developed a family of soldier power gensets targeted to fill the capability gap for lightweight, portable power generation. These generators use COTS gasoline engines that are modified to use tactical fuels (JP-8, Jet A JP-5, DF2, etc.) using PCI’s fuel conditioning technology. These devices have been tested to meet the harsh environmental and operations demands of the US Military and are easy to start, operate and maintain. These generators have been selected for development by the US Army for their Platoon Power Generation (PPG) and Small Tactical Electric Power (STEP) Lightweight programs.

The devices have been developed to act as remote power sources, battery charger power sources, stand-alone generators and vehicle APU’s.With an integrated starter generator these units can be started and stopped with the push of a button, or remotely via operator or machine signals, offering a uniquely qualified power source. The units allow for both onboard and remote fuel tanks, expanding the possibilities for portable and long duration, remote power generation for warfighters, remote sensors, or any other power need.

The devices have been developed to act as remote power sources, battery charger power sources, stand-alone generators and vehicle APU’s.With an integrated starter generator these units can be started and stopped with the push of a button, or remotely via operator or machine signals, offering a uniquely qualified power source. The units allow for both onboard and remote fuel tanks, expanding the possibilities for portable and long duration, remote power generation for warfighters, remote sensors, or any other power need.

More broadly, PCI has developed an ultra-compact solution that enables inexpensive lightweight commercial spark-ignited engines to run on multiple fuels (including diesel, biofuels and JP-8) for a wide variety of applications including a single person portable generator for remote power, backup telecommunications, first responders, homeland security and marine power.

PCI’s systems have the advantage of being much lighter in weight than diesel generators of comparable output. They can reduce the need to carry two fuels for recreational vehicle and commercial truck auxiliary power / anti-idle units. This also increases safety by eliminating gasoline and propane from marine power generation applications and replacing it with diesel, a safer, more suitable fuel.

PCI’s systems have the advantage of being much lighter in weight than diesel generators of comparable output. They can reduce the need to carry two fuels for recreational vehicle and commercial truck auxiliary power / anti-idle units. This also increases safety by eliminating gasoline and propane from marine power generation applications and replacing it with diesel, a safer, more suitable fuel.

PCI’s system is composed of:

- reliable commercial engines

- state of the art power electronics

- fuel conditioning unit

- robust packaging

- MIL STD electronics

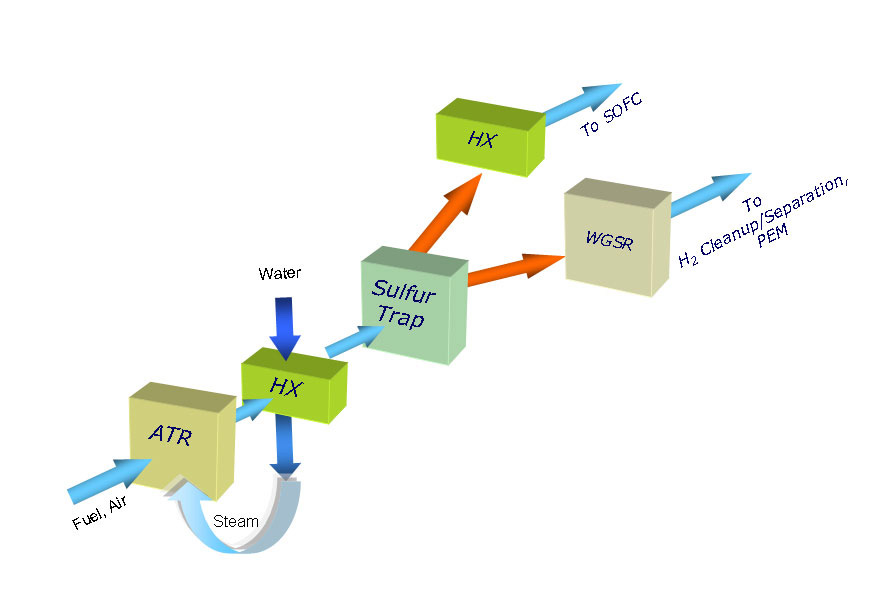

Our next generation solutions allow for power of remote devices using Fuel Cell Technology combined with PCI’s unique fuel conditioning devices. PCI has developed an ultra-compact fuel processor for solid oxide fuel cell systems. Current work with the Diesel and JP-8 fuel reformer has shown that autothermal reforming (ATR) is the best choice of technology to maintain a balance among size, weight, performance, durability, sulfur tolerance and total cost. These systems are being developed as future generation power sources, further advancing PCI’s mission to provide lightweight, quiet, clean and efficient power generation devices to our warfighters.

Contact PCI to learn more about how our solutions may be adapted for your needs.

Internal Combustion engine augmentation

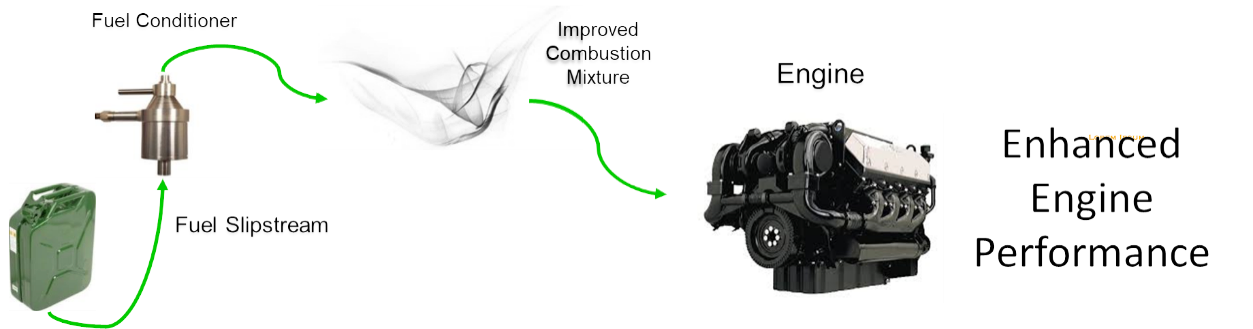

PCI’s Internal Combustion Engine system takes a slipstream of incoming fuel and creates a high octane, highly combustible mixture that is injected into the engine with standard fuel. This method positively impacts engine performance, reduces emissions and enables improved engine efficiency. PCI’s engine augmentation has proven performance on both spark and compression ignition engine systems.

Benefits:

- Improved combustion stability (lower coefficient of variation (COV) in indicated mean effective pressure (IMEP))

- Lower COV of IMEP with H2 up to 75% reduction

- Significantly extended dilution limit @ low COV

- Improvement in Break Specific Fuel Consumption (BSFC)

- Higher power

- H2/syngas augmentation increases peak Brake Mean Effective Pressure (BMEP)

- Lower emissions

- Significant reduction in NOx, HC, CO, PM

- Lower brake-specific NOx up to 50% reduction

- Lower brake-specific HC up to 50% reduction

- Lower brake-specific CO up to 40% reduction

- Reduction in Required Ignition Discharge Energy

- Reduced emissions at cold-start

- NOx reduction at steady state

- Faster combustion:

- Reduced ignition delay enabled 7 – 16 degrees of spark advance

- Lean tolerance:

- Internal + External Dilution up to 77% increase Tolerance

Contact PCI to learn more about how our solutions may be adapted for your needs.

Specialty Products

PCI is in various stages of developing other new products than those in its primary product groups (fuel processors, air cleaners, combustors and burners/oxidizers):

- Advanced Cetane Analyzer

- Catalytic Glow Plugs

- Chemicals Reactors

- Fast Lightoff Catalytic Converter

- Catalytic Liners

- Flashback Arrestors

We welcome potential customer and partner interest in these products.

Contact PCI to learn more about how our solutions may be adapted for your needs.

Low NOx, High Efficiency Catalytic Combustor

Catalytic combustion offers gas turbines and other large combustion systems the potential to achieve high flame stability (with near-zero hydrocarbon and carbon monoxide emissions) while also operating cool enough to have near-zero NOx emissions. The result can be ultra-low emissions without efficiency penalty or the costs of post-combustion NOx controls, as well as substantially broadened low NOx turndown arising from improved flame stability. Compared to the high costs of implementing post-combustion controls, our catalytic combuustor offers significant economic advantage to the combustor owner.

Dr. William Pfefferle, PCI's chief scientist, invented the original catalytic combustor. Over time, many parties have explored the concept but a perennial challenge to making commercial catalytic combustors has been the difficulty in achieving both high enough catalytic reaction while simultaneously avoiding catalytic over-reaction. PCI’s patented technology is a breakthrough in this area that unlocks the long sought potential of catalytic combustion.

Conventionally, lean premixed combustion, the current dominant gas turbine combustor technology, balances high flame stability against cool maximum firing temperatures, achieving near-zero hydrocarbon and carbon monoxide levels while producing NOx in the high single digit ppm range. If low single digit ppm NOx standards are to be met, then post-combustion controls such as selective catalytic reduction (SCR) systems are used.

The Catalytic combustor (sometimes called a catalytically-stabilized combustor) increases gas phase combustion stability by catalytically reacting a portion of the fuel, increasing overall gas phase reactivity and flame speed. Reacting a portion of the fuel in the catalytic region of the combustor improves flame stability as well as creating the conditions for more rapid, complete combustion. Extending flame stability provides many opportunities for gas turbines including the ability to burn lean enough to avoid NOx formation as well as achieve extended low NOx turndown. In the case of PCI’s technology, the combustor’s fuel flexibility is also substantially broadened, plus the technology can burn low BTU fuels that otherwise would require supplementation.

PCI is developing its RCL® catalytic combustion technology in several designs for ultra-low emission power generation gas turbines. PCI's full catalytic combustors seek to minimize NOx emissions from gas turbines, while its catalytic pilot burners are a partially-catalytic design that is easy to implement into existing lean premixed/dry low NOx designs. Our microturbine catalytic combustor addresses the unique needs of microturbines. Our downhole catalytic combustor/steam generator adapts RCL® technology for use downhole in an oil or gas production wellbore to provide thermal stimulation for production of oil and gas. PCI's oxyfuel combustor is directed to achieving effective combustion of oxygen and fuel in the presence of steam in IGCC and related systems.

- Full catalytic combustor

- Catalytic pilot

- Downhole steam generator for oil and gas production

- Microturbine catalytic combustor

- Oxyfuel combustor

- Soil Remediation

- Soil Disinfestation

Contact PCI to learn more about how our solutions may be adapted for your needs.

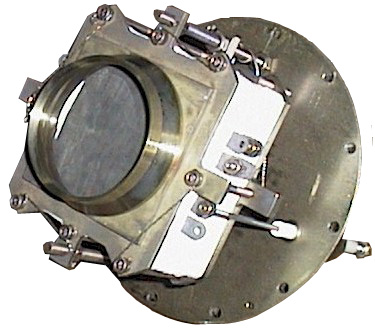

Microlith® Air Cleaners

Precision Combustion, Inc. (PCI) is developing air cleaning applications focused on control of Volatile Organic compounds (VOC's), Sulfur and other air pollutants. Applications include air treatment systems for spacecraft, submarines and collective protection shelters. These reactors include temperature and pressure swing adsorption/desorption approaches. They consist of resistively heated substrates coated with sorbents. Standard sorbents (e.g. zeolites) are coated on the substrates and are regenerated by various combinations of heating and pressure swing.

AIR CLEANERS

Air cleaner performance benefits

Microlith® catalytic air cleaners offer several performance benefits over alternative technologies.

- Ultra-compact size and low weight

- Direct electrical heating of the conductive substrate utilizing low power

- High energy and conversion efficiency

- Reduced maintenance and power requirements

- Improved durability for long term reliable operation

The technology has been developed in two embodiments, a Trace Contaminant Oxidizer for VOC's and CO and a Trace Contaminant Adsorber for CO2 and other Spacecraft Maximum Allowable Concentration (SMAC) compounds.

Additional papers on PCI's air cleaner technology

"Unique Metal Monolith Catalytic Reactor for Destruction of Airborne Trace Contaminants." SAE 972432.

"Demonstration of an Ultra-Short Channel Metal Monolith Catalytic Reactor for Trace Contaminant Control Applications" SAE 1999-01-2112.

"Performance Characterization of a Prototype Ultra-Short Channel Monolith Catalytic Reactor for Air Quality Control Applications." SAE 2005-01-2868.

Contact PCI to learn more about how our solutions may be adapted for your needs.