Advanced Cetane analyzer

Simple, robust design. Accurate and repeatable results.

PCI is developing a highly innovative advanced fuel quality analyzer for quickly and accurately measuring the cetane number (CN) of diesel, jet fuels, and bio-diesels. It performs a direct analysis of the fuel to provide an accurate measurement of the cetane number – as compared to inferring the CN with a cetane index methodology. This device replaces alternative measurement technologies that are expensive, time consuming and that require skilled operators.

- Robust calibration consistent with ASTM Standards D-613 and D-6890 process test results

- Accurate on fuels containing cetane additives/enhancers

- Measurement based on fuel combustion properties and proprietary algorithms

PCI’s device has wide application in the manufacture of fuels to improve process and cost efficiencies, as well as with end-users to improve operations and maintain fuel integrity.

Fuel production applications: Pre-process (input material validation), In-process (quality monitoring) and Post-process (product verification)

End-user applications: in-field fuel quality verification, stored fuel integrity, laboratory fuel analysis, quality check on spot-purchased fuel, etc.

Future development of the product will extend its capabilities to the measurement of octane in gasoline.

Contact PCI to learn more about how our Cetane Number Analyzer can be applied to your situation and business requirements.

Catalytic Chemical Reactors

PCI is developing novel approaches to chemicals manufacture using new catalytic systems, seeking improved selectivity and yield as well as other advantages, offering what could be significant economic benefits to chemical plants, pharmaceutical manufacturing and petroleum refineries. Such reactors could also generate capital cost savings over traditional processes.

PCI's approach is distinguished by the novelty of its reactors, both in catalyst structure and in mode of operation. Reactor design opportunities are highly customized in nature, and include the following:

- Novel reactor strategies for addressing challenging chemical transformations, including solid acid alkylation, oxidation processes and methane upgrading.

- Short contact time Microlith reactors for specialized chemicals manufacture.

Contact PCI to learn more about how our solutions may be adapted for your needs.

We welcome potential customer and partner interest in these products.

Contact PCI to learn more about how our solutions may be adapted for your needs.

Microlith® Fast Lightoff Catalytic Converter

Microlith® technology offers multiple benefits for automotive and other internal combustion engine aftertreatment applications. The low thermal mass is especially important for quick catalyst lightoff in order to deal with automotive cold start emissions. The PCI catalytic converter can achieve greater conversion effectiveness per unit size material, with up to 20-fold reduction in volume and weight, as well as reduction in precious metal catalyst requirements, compared to long channel monoliths.

The combination in a passive converter of faster lightoff, smaller size, lower weight, increased effectiveness and lower cost is attracting significant interest from the automotive and marine industries. Prototypes have been tested with major U.S. engine manufacturers. A two stroke application of the technology is also being developed as well as a formaldehyde oxidation catalyst for reciprocating natural gas engines. Test results conducted on a 1.9L Ford Escort, in collaboration with Ford Motor Co., demonstrated emissions reduction that exceeds the Ultra Low Emission Vehicle standards (ULEV) (SAE Technical Paper # 971023). Durability has been proven through multiple "hot vibe" tests (950oC,28g's, 100hz) and engine aging tests.

Contact PCI to learn more about how our solutions may be adapted for your needs.

Additional Publications

"Laboratory Evaluation of Ultra-Short Metal Monolith® Catalyst" SAE 980672.

"Development and Performance of Microlith® Light-off Preconverters for LEV/ULEV." SAE 971023.

"Rapid Thermal Response Catalyst for Treatment of Automotive Exhaust" Materials Research Society, Symposium Proc. Vol. 454, 1997.

"Reduction of Formaldehyde Emissions from Pipeline Compressor Drivers" GRI-02/1035, Gas Research Institute.

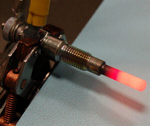

Catalytic Glow Plugs

PCI is developing catalytic glow plug technology to expand the capabilities of engines using heavy fuels, such as diesel or JP-8. These fuels are less volatile during transport and relatively easier to refine from petroleum than their traditional counterparts (e.g. aviation gasoline), but heavy fueled engines have historically been plagued by reliability issues. PCI's catalytic glow plug technology helps solve reliability problems thus providing a safer and less expensive solution for heavy fuel applications that require achieving optimized ignition.

With the support of United States Air Force in the form of a Phase II SBIR Contract, PCI is continually optimizing its catalytic glow plug design to offer manufacturers a reliable method of achieving:

- more rapid starting

- better operability

- lower required compression ratios

- improved igniter life

- reduced energy requirement

- overall reduction in system size and weight

PCI’s catalytic glow plugs have been proven to improve the cold start capability of diesel engines by lowering the required temperature for ignition and reducing the cranking time before engine start. PCI's catalytic glow plugs have also been demonstrated to support ignition in low compression ratio engines at lower input powers than conventional glow plugs. More specifically, this breakthrough technology is ideally suited for rotary engine applications such as in unmanned aerial vehicles (UAV) where weight, size, and operability are primary concerns. PCI has also integrated its resistively-heated catalytic surface technology into fuel injection systems to produce catalytic injectors and torches for a variety of applications including gas turbines. Likewise, catalytic glow plugs can be especially useful for high compression engines burning natural gas and other alternative low cetane fuels.

Compression engine manufacturers looking to improve ignition performance should contact us to discuss how an ignition assistance system using catalytic glow plugs can help them.

Contact PCI to learn more about how our solutions may be adapted for your needs

<--

- Advanced Cetane Analyzer

- Catalytic Glow Plugs

- Chemicals Reactors

- Fast Lightoff Catalytic Converter

- Catalytic Liners

- Flashback Arrestors

-->

Catalytic Liners

PCI can catalytically coat conventional gas turbine liners for new and existing gas turbines. Our process enhances the opportunity for lower emissions by placing catalyst within the combustion gas stream. Coated catalytic liners offer to achieve up to 15% reduction of carbon monoxide and unburned hydrocarbons without a major gas turbine system redesign. PCI has produced catalytic liners which are in service in the field and have demonstrated reduced CO emissions.

Contact PCI to learn more about how our solutions may be adapted for your needs