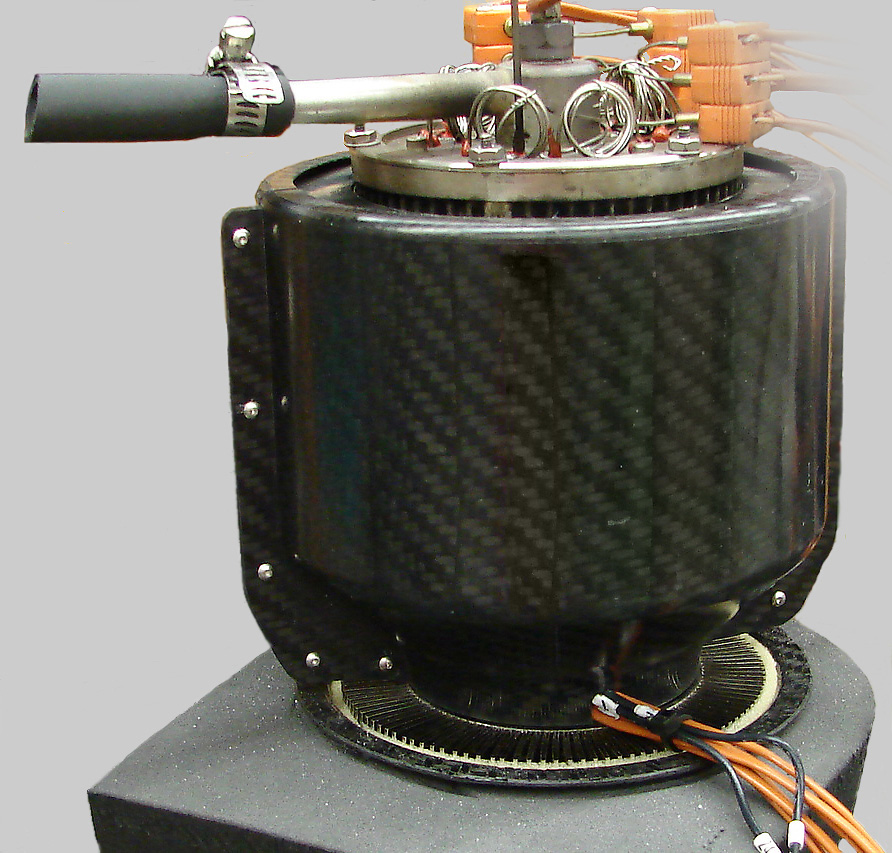

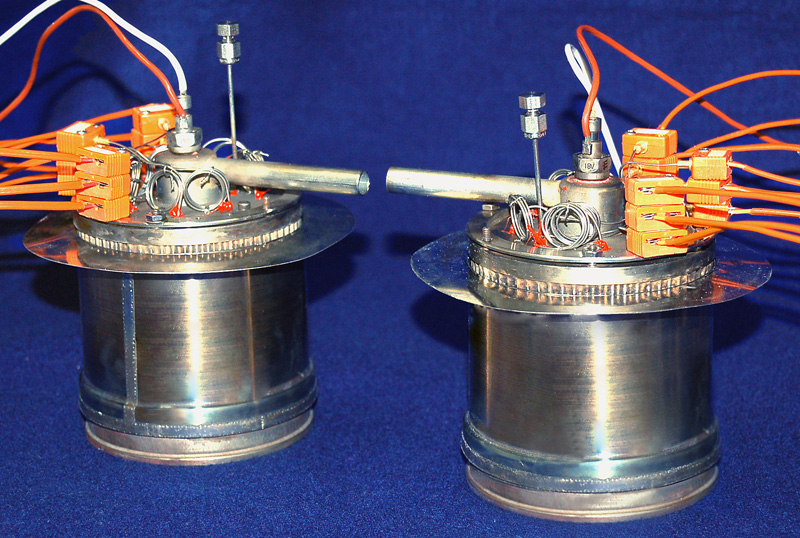

Stirling Engine Burner

PCI is developing novel catalytic burners for Stirling engines. External combustion engines, like the Stirling engine, have benefits over their internal combustion counterparts due to their ability to remain completely sealed from the elements and their nearly silent operation. Stirling engines are inherently robust, quiet, and only require an external heat source for operation. These characteristics make these engines ideal candidates for military and commercial applications where clean, quiet power is desired. Unfortunately, burners using logistics fuels, such as JP-8 or diesel, have struggled to meet acceptable efficiency requirements and are troubled by problems such as sulfur intolerance or 'wet stacking'. PCI has developed a Stirling engine burner that thrives on high sulfur logistics fuels and is continuously optimizing the design to offer engine manufacturers a unique solution for:

- Various engine sizes (40 We-3 kWe)

- Different engine designs

- Quick startup

- High system efficiency (15-20%)

- Extreme compactness and light weight

- Fuel atomization and mixing

With the support of the United States Army in the form of a Phase II SBIR contract, PCI has adapted its catalytic technology to create a highly efficient and ultra-compact distillate fuel burner for generating electrical power from Stirling engine systems. PCI's Stirling engine burner features a portable lightweight design that is easily scalable for large kW-scale Stirling engines as well as adaptable for various fuel types. With minimal maintenance, PCI's burner will enable dependable battlefield power generation in near silence with low emissions and low thermal profile using logistic fuels. Financial benefits will stem from better efficiency and the reduced logistic burden of supplying power and energy to the field, which is often accomplished using numerous batteries or noisy portable generators to support squad missions.

We encourage manufacturers and users seeking to explore the possibilities of portable low emission electricity production or high efficiency fuel combustion to contact us to explore how PCI's Stirling engine burner technology may help them.

Contact PCI to learn more about how our solutions may be adapted for your needs.

PCI's Burners and Oxidizers

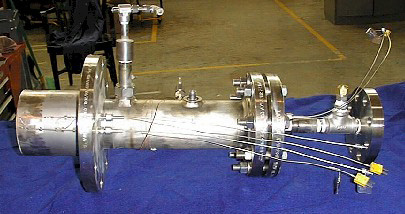

Fuel Cell System Oxidizer

The rapidly advancing fuel cell industry is persistently striving to become safer, less costly, and more efficient each day. PCI is supporting that mission with our unique burner technology. We are helping to pioneer fuel cell development by adapting our innovative burners to effectively complement emerging advances in the field. Specifically, PCI is continuously enhancing the design of three demonstrated technologies:- Fuel cell system inerting burners

- Fuel Reformer start burners

- Anode gas oxidizers

As the fuel cell industry evolves, technical obstacles continue to present themselves. Dangerous and complex system startups are examples of problems that developers must constantly manage. PCI’s inerting burner and fuel reformer start burner are two innovations that will help alleviate the innate difficulties of fuel cell system startups. Our inerting burners ensure that hydrogen left in the system is safely oxidized prior to startup to prevent potentially dangerous system startup failures. PCI’s fuel reformer start burners use unique catalytic technology to effectively provide appropriate levels of preheat for efficient fuel reforming. This technique can be extremely effective when preparing more traditional fuels such as diesel for fuel cell use.

Anode portions of fuel cells are often unable to employ all available hydrogen which can create potentially dangerous levels of flammable emissions. PCI’s anode gas oxidizer uses an innovative catalytic technology to not only oxidize these volatile tail-gas emissions, but to recycle waste heat. This recycled heat can boost overall system efficiency and provide a valuable heat source for other accessory applications.

Contact PCI to learn more about how our solutions may be adapted for your needs.

Burners and Oxidizers

Catalytic Burner

PCI has several very small to medium sized low NOx catalytic burner products in development. Our gas burner technology was developed under an NSF program with promising results including flameless catalytic combustion of natural gas with CO less than 2 ppm, CH4 less than 2 ppm and NOx less than 0.3 ppm. We have further developed this for use with other gases (such as butane, with which we have demonstrated 20 kWt power density per cubic inch. We developed JP-8 catalytic combustion capability as a DARPA PalmPower subcontractor and have demonstrated stable combustion with very high power density.

Applications include low NOx cook-top burners, industrial process burners and portable heaters, and other processes where a compact combustion zone achieving complete combustion with low emissions is desired. In addition, the ultra-compact ultra low NOx catalytic burner can be used as heat sources for energy conversion devices, such as Stirling engines and Thermoelectric, Thermophotovoltaic (TPV) and Thermionic generators.

Contact PCI for more information.

Burners and Oxidizers